A: Automatic PLC Operation, Big Capacity

B: Hydraulic Press, High Strengh of Block and Paver

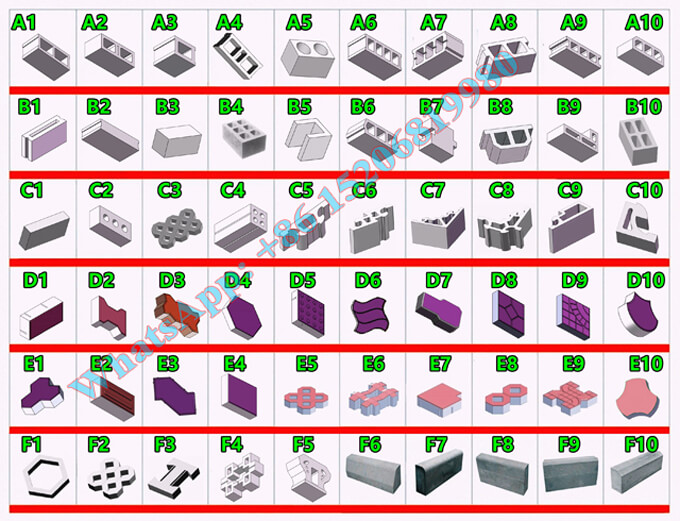

C: Produce Sizes of Hollow block, Solid Brick, Paver and Curbstone by changing molds

D: Suitable for Large-scale Block Factory

2. Produciton Capaicty of QT10-15 fully automatic concrete block making machine

QT10-15 fully automatic hydraulic block making machine can produce sizes of hollow block, solid brick, paver and curbstone by changing molds. the following are production capacity for some popular sizes of blocks and pavers.

| NO. | Block Size | Produciton Capacity | Photo |

| 1 |

Hollow/Solid Block 400*200*200mm (8 Inch) |

10 blocks in one mold 19200 blocks in 8 hours |

|

| 2 |

Hollow/Solid Block 400*150*200mm (6 Inch) |

12 blocks in one mold 23040 blocks in 8 hours |

|

| 3 |

Hollow/Solid Block 400*100*200mm (4 Inch) |

18 blocks in one mold 34560 blocks in 8 hours |

|

| 4 |

Hourdis Block 500*150*200mm |

10 hourdis in one mold 19200 hourdis in 8 hours |

|

| 5 |

S Shaped Paver 225*112.5*60/80mm |

24 pavers in one mold 38400 pavers in 8 hours |

|

| 6 |

I Shaped Paver 200*160*60/80mm |

18 pavers in one mold 28800 pavers in 8 hours |

|

| 7 |

Rectangle Paver 200*100*60/80mm |

27 pavers in one mold 43200 pavers in 8 hours |

|

3. Detailed Introduction of QT10-15 automatic hydraulic concrete cement block making machine

A:Electricity Power of QT10-15 automatic hydraulic block making line

| NO. | Item | Power | Function |

| A | PLD1200 batching Machine | 12KW | Automatic Batching raw material |

| B | JS750 Mixer | 38.6KW | Mixer Raw Material |

| C | Pallet Lifing Machine | 5.2KW | LIfting pallet into pallet box of block machine |

| D | 8m Belt Conveyor | 1.1KW | Carry mixed matrial from mixer to block machine |

| E | QT10-15 Block Machine | 45.5KW |

automatic material feeding system automatic pallet feeding system hydraulic station automatic PLC control |

| F | Block Sweeper | 2.2KW | Carry fresh block from block machine to stacker |

| G | Automatic Stacker | 3KW | Automatically stacking fresh block with 4-5 pallet |

|

Total Power: 108.7KW, Eelctricity must be 3 phase, 50/60HZ, 380V/440V/220V |

|||

Please click the following photos to watch more video about QT10-15 block machine

C: Worker Number: 5 Workers

One Worker to drive Loader for loading material into Batching Machine

One Worker to operate Mixer and Batching Machine

One worker to add pallet into block machine pallet box

One worker to Operate Block Machine

One Worker to Carry fresh block to Curing Sites

D: Factory Area: 2000-2500m2

Shelter Area: 60M2 (6*10M)

E: Pallet Number: 2000 Pallet. GiantLin Machinery recommend you Fiber (GMT) Pallet.

please click above photo to read advantages of fiber pallet for block machine

F: Material Ratio for Blocks

a: 10% Cement, 30% Sand and 60% Stone

b: 10% Cement and 90% Stone Powder

c: 10% Cement, 30% Fly Ash and 60% Stone Powder

G: Material Consumption

We take 400*200*200mm hollow block as example and 10% cement in Raw Material

| Size of Block | 400*200*200mm |

| PHoto of Block |

|

| Capacity | 19200 blocks in one day |

| Material Ratio | 10% Cement, 90% sand and Stone |

| Consumption of Cement | 28800 KG in one day |

| Consumption of Stone | 259200 KG in one day |

H: Maintance: QT10-15 autoamtic hollow solid block making machine is easy in maintance. please clean the mixer and mold after everyday Work and Fasten Screes and add lubriction oil to moving parts before every day work.

I: Install Sevice: We will supply you manual and install video. if you need, we also can send our engineer to your place to help you install machine and train your workers.

J: Guarantee Time: Two Year. We will supply free accessories with machine shippment and technical service and spare parts are avaible in all time.

By adopting lead technology from domestic and up-to date technology international, this machine has embodied the crystallization of Sino-Germany Wisdom------ technology-enabled, sophissticated design. The human design combined 24 years experirence in production. The strict Technological requirement make the machine have the following characteristic: Fine quality, stable and reliable performance, long working list, High strength of block and pavers, low cost, which embody the best quality of Jinda bock machine.

1. Material and Welding: Using the High-Strength Steel and Carbon Dioxide Protection Welding will Assure Jinda brick making machine stable running.

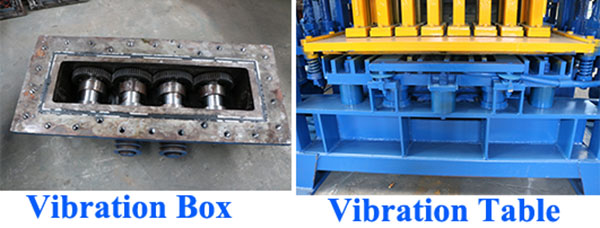

2. Vibration System: We use the Germany technology

A: provides more vertical vibration at the starts of the cycle which aids in compaction of the material in the molds and potentially reduces feed time

B: Higher speeds can provide a better product finish.

C: the ability to decrease speed of stripping of product can reduce culls and aids in the manufacture of hard-to -form products such as thin-walled block

D: Reduces horizontal mold movement during machine cycles for longer mold life

3. Mould Structure: We design the mould structure specially in order to change the mould easily and we use the new Heat Treatment and Carbonization to diffusing carbon into the Surface of steel. It will increase Hardness, Wear-resistance of the Surface of Mould, While Maintaining toughness and strength of the core of Mould. So Jinda Block Mould is more stronger nad twice life than ordinary mould.

Photos of QT10-15 Automatic Hydraulic Block Making Machine

GiantLin QT10-15 automatic hydraulic block making machine in production

Mexico Customer test GiantLin QT10-15 Automatic hollow block making machine

GiantLin QT10-15 automatic block making line in Kenya

GiantLin Customers Feedback and Comments from all over the World.

Contact Information

Linyi GaintLin Machinery Co., Ltd

WhatsApp: +86 15206819980

Wetchat:+86 15206819980

Email: chinamachinery123@gmail.com

Web: www.giantlinblockmachine.com

Mob.:+86 15206819980

E-mail:chinamachinery123@gmail.com

Website:www.giantlinblockmachine.com

Address:Zhuanbu Industrial Zone

Linyi CityShandong Province, China

Company Philosophy: Quality,Service,and Innovation