1. Advatange of QT6-15 automatic hydraulic concrete brick block making machine

A: Automatic PLC Operation, Big Capacity, Low Labour Cost

B: Hydraulic Press, High Strength of Block and Paver

C: Produce sizes of hollow block, solid brick, hourdis, paver and curbstone by changing molds.

D: Suitable for Large and Medium-scale Block Factory

2. Production Capacity of QT6-15 automatic hydrulic cement brick block making machine

QT6-15 automatic hydraulic cement brick block making machine can produce sizes of hollow block, solid brick, interlocking paver, hourdis and curbstone by changing molds.

The following are production capacity for some popular sizes of blocks and pavers.

| Item | Size of Block | Production Capacity | PHoto of Block |

| 1 |

Hollow/Solid Block 400*200*200mm (8 Inch) |

6 blocks in one mold 11520 blocks in 8 hours |

|

| 2 |

Hollow/Solid Block 400*150*200mm (6 Inch) |

7 blocks in one mold 13440 blocks in 8 hours |

|

| 3 |

Hollow/Solid Block 400*100*200mm (4 Inch) |

10 Blocks in one mold 19200 blocks in 8 hours |

|

| 4 |

Hourdi Block 500*150*200mm |

5 blocks in one mold 9600 blocks in 8 hours |

|

| 5 |

S Shaped Paver 225*112.5*60/80mm |

14 pavers in one mold 26880 pavers in 8 hours |

|

| 6 |

I Shaped Paver 200*160*60/80mm |

15 pavers in one mold 28800 pavers in 8 hours |

|

| 7 |

rectangle Paver 200*100*60/80mm |

20 pavers in one mold 38400 pavers in 8 hours |

|

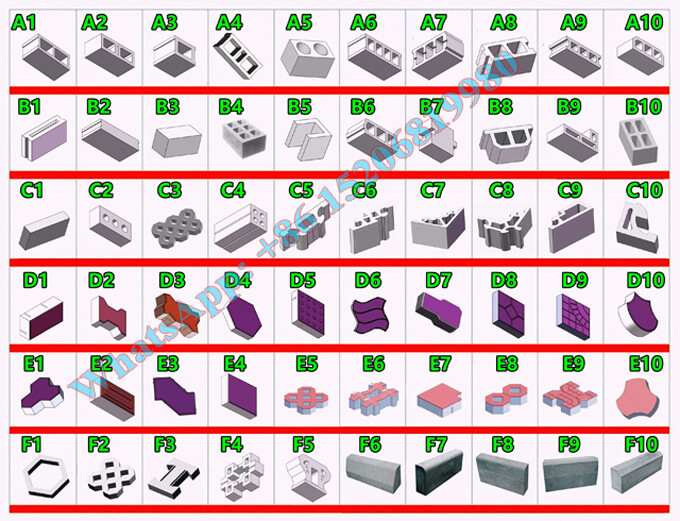

the following are some designs of blocks and pavers for your reference:

3. Detailed Description of QT6-15 automatic hydrauic concrete block moulding machine

A: Electrick Power for QT6-15 automatic block making Line:

| No. | Machine | Power | function |

| A | PLD800 Batching Machine | 9KW | Automatic Batching raw material |

| B | JS500 Mixer | 25.1KW | Mixing raw material with water |

| C | 6M Belt Conveyor | 0.75KW | Carry mixed material from Mixer to Block Machine |

| D | QT4-15 Block Machine | 29.7KW |

Automatic material feeding system Automatic Pallet feeding system Hydraulic Station Automatic PLC Control |

| E | Automatic Stacker | 3KW | Automatically Stacking fresh Block with 4-5 pallet |

|

|

Barrow | without | Carry Fresh Block from Stacker to Curing Sites |

|

Note: otal power: 67.75KW, Electricity must be 3 phase, 50/60HZ, 380V/440V/220V |

|||

B: Working Video of QT6-15 automatic hydrauic concrete cement brick block making machine

B: Worker Number: 5 Workers

One Worker to drive Loader for loading material into Batching Machine

One Worker to operate Mixer and Batching Machine

One worker to add pallet into block machine pallet box

One worker to Operate Block Machine

One Worker to Carry fresh block to Curing Sites

C: Factory Area: 2000-2500m2

Shelter Area: 60M2 (6*10M)

D: Pallet Number: 2000 Pallet. GiantLin Machinery recommend you Fiber (GMT) Pallet.

please click above photo to read advantages of fiber pallet for block machine

E: Material Ratio for Blocks

a: 10% Cement, 30% Sand and 60% Stone

b: 10% Cement and 90% Stone Powder

c: 10% Cement, 30% Fly Ash and 60% Stone Powder

F: Material Consumption

We take 400*200*200mm hollow block as example and 10% cement in Raw Material

| Size of Block | 400*200*200mm |

| PHoto of Block |

|

| Capacity | 11520 blocks in one day |

| Material Ratio | 10% Cement, 90% sand and Stone |

| Consumption of Cement | 17280 KG in one day |

| Consumption of Stone | 155500 KG in one day |

G: Maintance: QT6-15 autoamtic hollow solid block making machine is easy in maintance. please clean the mixer and mold after everyday Work and Fasten Screes and add lubriction oil to moving parts before every day work.

H: Install Sevice: We will supply you manual and install video. if you need, we also can send our engineer to your place to help you install machine and train your workers.

I: Guarantee Time: Two Year. We will supply free accessories with machine shippment and technical service and spare parts are avaible in all time.

Congo customer inspect GiantLin QT6-15 automatic building block making machine

GiantLin QT6-15 automatic concrete solid block making machine in Tanzania

GaintLin QT6-15 automatic block making line is ready for transport

6. GiantLin Customers Feedback and Comments from all over the World.

7. Contact Information

Linyi GaintLin Machinery Co., Ltd

WhatsApp: +86 15206819980

Wetchat:+86 15206819980

Email: chinamachinery123@gmail.com

Web: www.giantlinblockmachine.com

Mob.:+86 15206819980

E-mail:chinamachinery123@gmail.com

Website:www.giantlinblockmachine.com

Address:Zhuanbu Industrial Zone

Linyi CityShandong Province, China

Company Philosophy: Quality,Service,and Innovation