1. Advantages:

A: One Blockin One Time, 2400 Blocks per 8 Hours

B: Diesel Powered Engine ( Electric Option Available)

C: Mobile Block Machine with Road Tyres and Tow Hitch

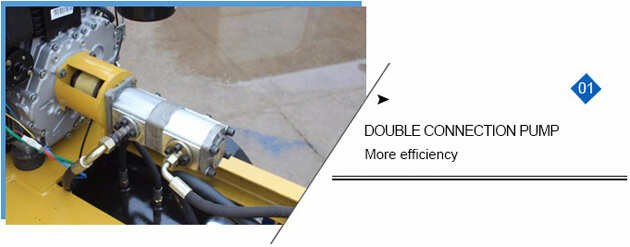

D: Hydraulic Press, Up to 21Mpa

E: Best Choice for Block Production in Remote Areas and Building Sites

2. Parts List of M7MI soil cement interlocking hydraform block making machine

NO.

Name of Parts

Function

A

Mold

For 230*220*115mm Hydraform Block

B

Material Hopper

Storage Material for Mold

C

Diesel Engine

6.75KW (Best Brand in China)

D

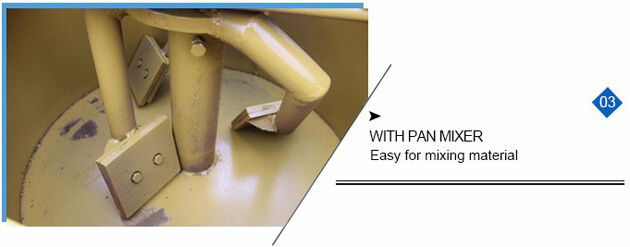

Pan Mixer

Mix Rawing Material

E

Road Tyres

Movement from one site to other

F

Tow Hitch

Connect with truck or Car

G

Operation Handle

Operate block machine

3. Videos List for Machine working and operation of M7MI soil cement interlocking hydraform block making machine

4. Designs of blocks which are produced by M7MI soil cement interlocking hydraform block making machine

5. Workers Number: 6 Workers in Total

Two workers for loading material into pan mixer

One worker for loading mixed material into material hopper

One Worker for loading material from hopper to mold

one worker for operating block machine

one Worker for for carry fresh block from mold

6. Material Ratio for Hydraform Block: 5%-10% cement and 90-95% soil

7. Raw Material Consumption in one day

Here we take 230*220*115 mm Hydraform Block as example and Recommend 8% cement

size of Block

230*220*115mm

Photo of Block

![]()

Material Ratio

8% cement and 92% soil

Strength of Block

7-8Mpa

Capacity of Block

2400 Blocks in one Day

Consumption of Cement

2300 KG per Day

Consumption of Soil

26500 KG per Day

Consumption of Diesel Oil

16L Per Day

8. How to Cure Blocks

Fresh Blocks are stacked and covered with black plastic to avoid moisture loss. The blocks are then watered daily to creat a greenhouse effect, allowing the cement to harden and the blocks to strengthen. Cure your blocks for a minimum of 7 days and allow the blocks to dry to another 7 days before building. This will ensure strong good quality blocks.

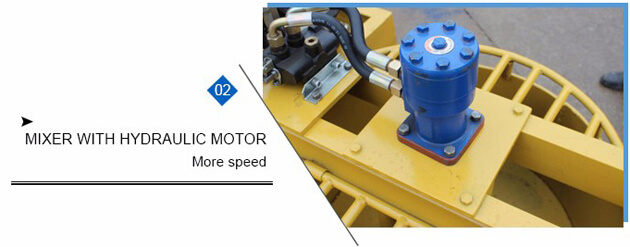

9. High Machine Qualtiy is from Excellent Parts and Manufacturing Technology.

Mob.:+86 15206819980

E-mail:chinamachinery123@gmail.com

Website:www.giantlinblockmachine.com

Address:Zhuanbu Industrial Zone

Linyi CityShandong Province, China

Company Philosophy: Quality,Service,and Innovation