1. Advantages:

A: Diesel Power or Electric Power

B: 2 Bricks in One Time and 2800 Bricks in 8 Hours

C: Semi automatic, Easy Operation

D: Produce Designs of Interlocking Brick, Pavers and Hydraform Block by changing molds.

E: Suitable for Medium-scale Brick Factory

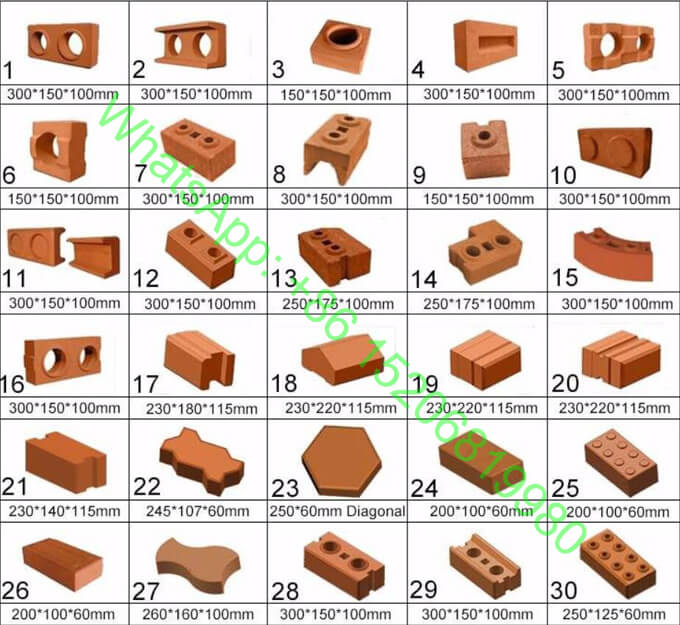

2. Designs of Bricks and Pavers

GL2-25 eco brava clay interlocking brick making machine can produce designs of interlocking ecologica bricks, lego bricks, pavers and hydraform blocks by changing molds.

The following are some designs of bricks for your reference.

3. Product Description

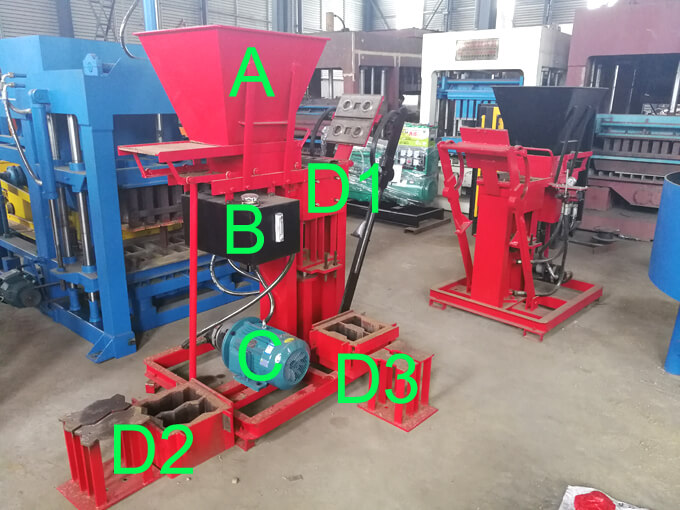

A: Part Name of GL2-25 eco brava clay interlocking brick making machine

| Item | Name |

Function |

|

| A | Material Hopper |

Storage of material for mold |

|

| B | Hydraulic Station |

Storage of Hydraulic Oil |

|

| C | Electiric Motor or Diesel Engine |

4KW /5.5HP |

|

| D1 | Mould |

Produce interlocking brick |

|

| D2 | Extra Mold |

Changing mold for different design of brick and pavers |

|

| D3 | Extra Mold |

Changing mold for different design of brick and pavers |

|

|

Total Power: 4KW/5.5HP. Electriicty must be 3 phase, 50/50HZ, 380V/440V/220V |

|||

B: Working Video List of GL2-25 eco brava clay interlocking brick making machine

please click below photo to watch working video

C: Workers Number: 3 Workers in Total

One Worker for Loading soil into Material Hopper

One Worker for Operating Brick Machine

One Worker for Carry fresh brick to curing sites

D: Factory Area; 600-1000M2

E: Material Ratio for Bricks: 5%-10% cement and 90-95% Soil

F: Raw Material Consumption in one day

We take 300*150*100 bricks as example and recommend 8% cement

| Size of Brick | 300*150*100mm |

| Photo of Brick |

|

| Material Ratio |

8% cement and 92% soil |

| Strength of Brick | 6-7Mpa |

| Capacity of Brick | 2800 bricks in one day |

| Consumption of Cement | 1200 KG in one day |

| Consumption of Soil | 15000 KG in one day |

G: Install Service:

We will ship machine in whole one. you only need connect with electricity, then machine can work. we also supply customers operation manual and Video

H: Guarantee time: Two years.

4. Photos Show of GL2-25 eco brava clay interlocking brick making machine.

GiantLin GL2-25 semi automatic clay interlocking brick making machine in production

GiantLin Mold for interlocking lego bricks

GiantLin GL2-20 soil cement interlocking brick making machine ready

GiantLin GL2-20 eco brava clay interlocking block making machine

5. GiantLin Customers Show:

6. Related Information about Soil Interlocking Bricks:

1. What is Good Soil for Interlocking bricks

2. How To Prepare Soil Cement Material for interlocking Bricks

3. How To Cure Soil Interlocking Bricks

4. How To Stack Soil Interlocking Bricks

5. How To Transport Soil Interlocking Bricks

6. The Most Popular Designs of Soil Interlocking Bricks

7. Contact information:

Linyi GiantLin Machinery Co., Ltd.

WhatsApp: +86 15206819980

Wechat; +86 15206819980

Email: chinamachinery123@gmail.com

Web: www.GiantLinBlockMachine.com

Mob.:+86 15206819980

E-mail:chinamachinery123@gmail.com

Website:www.giantlinblockmachine.com

Address:Zhuanbu Industrial Zone

Linyi CityShandong Province, China

Company Philosophy: Quality,Service,and Innovation